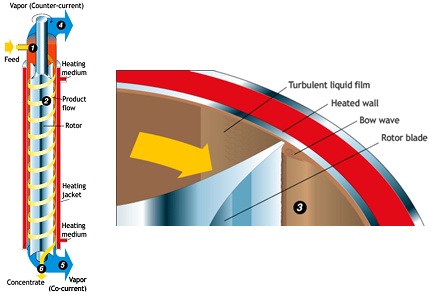

Separation of impurities and low volatility, high molecular weight components from mineral oils is carried out in thin film evaporators. It is essential to achieve high temperature and lowest possible vacuum to provide the maximum re-refining of waste mineral oil. In addition, the residence time of the oil should be minimized to prevent it from degradation. Thin film evaporator comprises an upright cylindrical vessel with movable or fixed vertical blades attached to a concentric rotor shaft. Thin layer of liquid formed on the inside wall of the vessel reaches high temperature quickly. Volatile components evaporate and are condensed and collected. Separation of impurities and low volatility, high molecular weight components from mineral oils is carried out in thin film evaporators. It is essential to achieve high temperature and lowest possible vacuum to provide the maximum re-refining of waste mineral oil. In addition, the residence time of the oil should be minimized to prevent it from degradation. Thin film evaporator comprises an upright cylindrical vessel with movable or fixed vertical blades attached to a concentric rotor shaft. Thin layer of liquid formed on the inside wall of the vessel reaches high temperature quickly. Volatile components evaporate and are condensed and collected.

Short-path evaporators are designed with a condenser placed inside the equipment body. The main reason to carry out different designs for classical and short-path evaporators is the fact that classical types can only be lowered to 1mbar working pressure while short-path evaporators can reach to 0.001mbar internal pressure. |